Process Mass Spectrometer

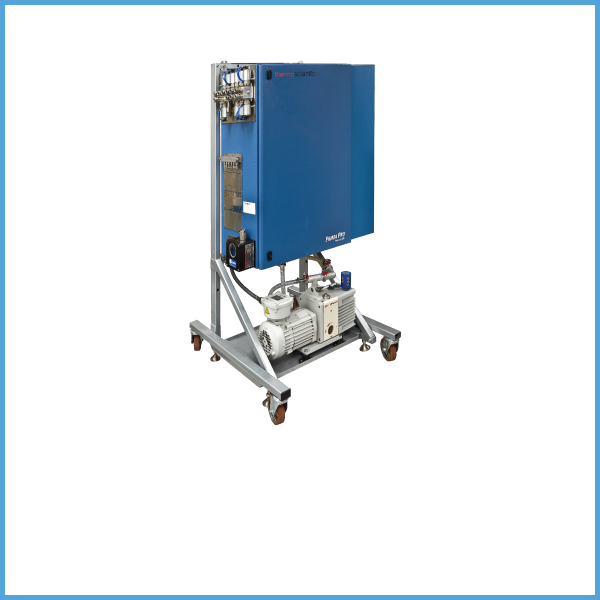

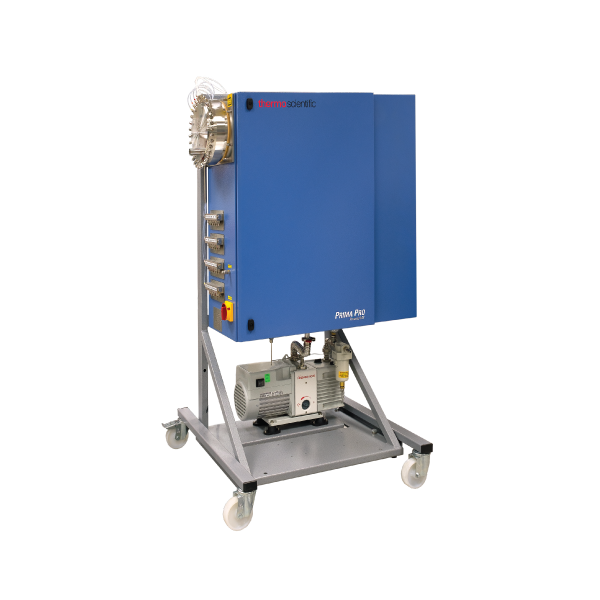

Prima PRO Process MS

A reliable and precise online gas analyser designed to optimise process efficiency and maximise product yield in various industries, featuring magnetic sector technology, a unique RMS inlet system, and exceptional precision.

Last updated: June 29, 2024

Prima PRO Process Mass Spectrometer

Precise, efficient and versatile gas analyser

The Thermo Scientific™ Prima PRO Process Mass Spectrometer is a state-of-the-art gas analyser engineered to optimise gas analysis in a wide range of industries, including petrochemical, iron and steel, and biotechnology. Equipped with advanced magnetic sector technology, the Prima PRO ensures exceptional precision, accuracy, and stability in gas analysis.

The Prima PRO sets new standards for efficiency with its unique RMS inlet system. No longer do you need multiple gas chromatographs for simultaneous analysis of multiple gas samples. The Prima PRO enables you to analyse up to 64 gas samples simultaneously, saving you time, resources, and maintenance efforts.

Designed with a fault-tolerant and rugged construction, the Prima PRO guarantees exceptional reliability and availability, surpassing 99.7%. Featuring automated calibration intervals of up to 90 days, it reduces the frequency of manual calibrations, saving you valuable time and effort. Its intuitive interface and auto-tune capabilities facilitate ongoing operation, enhancing productivity and efficiency in your gas analysis processes.

Whether you’re involved in natural gas processing, olefin production, iron processing, or other critical industrial processes, the Prima PRO is tailored to meet your specific needs. It empowers you to monitor and analyse gases with precision, ensuring optimal process performance and high product yield across a range of applications.

Your benefits

- Unmatched precision and stability for reliable gas analysis results

- Unique RMS inlet system enables simultaneous analysis of up to 64 gas samples

- Exceptional efficiency, eliminating the need for multiple gas chromatographs

- Fault-tolerant design ensures high availability, exceeding 99.7%

- Simplified maintenance procedures and automated calibration intervals up to 90 days

- Versatile applications in petrochemical, iron and steel, and biotechnology industries

- Streamlined operation and enhanced productivity with intuitive interface and auto-tune capabilities

- Compact footprint eliminates the need for a large shelter, saving space requirements

| Technical Specifications* | *Subject to change without notice | |

|---|---|---|

| Ion source | Enclosed electron impact with dual filaments, temperature controlled (settable over range 120-200°C, to ± 0.1°C) | |

| Analyzer type | Scanning, laminated electromagnet, 6 cm radius, 80° deflection | |

| Mass range | 1-200 amu | |

| Resolution | Switchable between two collector resolving slits, resolving powers of 60 (1mm) and 20 (4 mm) are standard. Optionally 140/85 (0.36 mm/0.69 mm) or 100/45 (0.56 mm/1.45 mm) or 140/45 (0.36 mm/1.45 mm) may be fitted | |

| Mass scale stability | Measured at mass 28 < 0.013 amu over 24 hours | |

| Peak shape | At 60 resolution, the ratio of the width of the flat-top (99% height width) to the base peak width (5% height width) 0.5 | |

| Abundance sensitivity | <250 ppm for 27/28 amu | |

| Detector | Faraday and optional Faraday/SEM dual detector | |

| Inlet | Temperature controlled micro-capillary with Molecular leak and bypass (standard configuration) | |

| Vacuum system | Turbo-molecular pump and external rotary pump Alternatively, turbo-molecular Pump and internal diaphragm pump | |

| Sample flow | Digitally measured and recorded for each stream for any instrument with RMS option | |

| Analysis time | 0.3-1.0 sec/gas component | |

| Ambient temperature | 12-42°C | |

| Lower Detection Double SEM | 10 ppb typical (may vary with gas matrix) | |

| Lower Detection Single SEM | 0.1 ppm typical (may vary with gas matrix) | |

| Lower detection faraday | 20 ppm typical (may vary with gas matrix) | |

| Precision | Better than 0.1% relative over 24 hours | |

| Linearity | <1% relative over a decade change in concentration (typical, application dependent) | |

| Dynamic range | 1 ppm – 100% (theoretical, application dependent) | |

| Stability | Better than 10% relative over one month | |

| Power requirements | 115/230 VAC, consumption 1500 VA | |

| Physical dimensions | 65 cm (26") L × 150cm (59") H × 70 cm (28in) W 300 kg (660lbs) configuration dependent | |

| Area classification options | General purpose: Z-purged Div 2 (optional); X-purged Div 1 (optional); CENELEC/ATEX Zone 1, IIC T3 (optional) | |

Need more information?

Visit the supplier’s website for more information about this product.